Propagation 2011 - LED Grow Light:

Calculations & Design

How big & how much?

Having decided on the best LED, then I need to know how many to use. This is a balance between size, power and cost. Size is perhaps the best place to start.

Size of Grow Light

The two hot beds I currently have are 4' by 2' each. Therefore it seems to me that I make 4 lights - each to cover an 2' by 2' bed area. This also means that they will be able to be moved easily - I might need to put them over the plants when I move them out of the cellar, or even to use in my sitting room over the potted plants there - to improve their lighting. So this decision starts to set out the space for placing the LEDs. The LED light viewing angle is 120 degrees. So this means that the distance above the bed will be about 10 inches. So the light does not need to be too wide. The final size has ended up 500mm long by 150mm wide ( i.e. 19.5" by 6") (this was also influenced by the cost and size of sheet aluminium for the light base plate).

Power

The number of LEDs per light now needs to be worked out. The LEDs need what is known as a constant current source. The LEDs are mounted in series and the voltage drop across each led is added and this then gives the voltage of the power supply. In the case of Cree XP-G LEDs the voltage drop at 1.25A is 3.4v. Common DC power supplies provide 12v, 24v and 48v. So which to choose? In the end I decided to go for 24v. However these are constant voltage and not constant current. What is also required is a constant current circuit. Fortunately these are simple and easy to make - see circuit diagram below. The regulator chips are < £1 each and easily available.

To ensure the constant current there needs to be a volt drop across R1 - 1.25v as well as a minimum across the regulator itself. when I do the maths, using 6 LEDs I get a minimum of 24.65v. So I had to buy 24v psu which had adjustable output voltages. To get 1.25A I need a 1 Ohm resistor for R1. Qed.

How efficient?

The LEDs consume 25.5W, the mains input to a 24v psu at 85% efficiency is 36.3W. Overall this is a 70% efficiency in LED power to mains power, not bad!

How much light? (and cost to run?)

For 6 XP-G LEDs at 1.25A I get 2022 lux or 77.34 µmol m-2 s-1 . Since I wanted as much as possible, I decided to have two sets of 6 LEDs per grow light i.e. 72.6W each, or 290W for all 4 - which, when I add the hot bed cables, I have approx 400W required - so for a 16 hour day then the cost to run is approx 64p per day - which I think is OK.

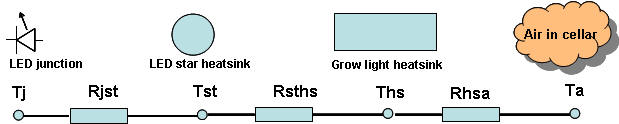

Thermal design

Since I want as much light out of the LEDs as possible, I need to keep the LED junction temperature, Tj, as low as possible. This is the temperature of the actual silicon chip bit of the LED. The maximum is 150 oC, but the life of the LED may be shortened if run this high continually - they should last 50,000 hours! Also the lower the Tj, the higher the light output - at 150 oC it is reduced to 72%, while at 50 oC it is reduced to 95%. So - how to keep it down?